Inhaltsverzeichnis

Setting a budget for custom packaging can be a daunting task, especially with the many factors involved in the decision-making process. As eCommerce continues to grow, brands are constantly searching for ways to enhance customer engagement through their products and packaging. While marketing campaigns and promotions are essential, one of the most direct and powerful ways to create customer loyalty is by delivering an unforgettable unboxing experience. The packaging you choose plays a critical role in this experience and, ultimately, in how customers perceive and interact with your brand.

However, when it comes to packaging, one of the most common questions businesses face is how to allocate a budget for custom packaging. While it may seem challenging to pinpoint an exact figure, once you understand your product needs, sales projections, and packaging requirements, the process becomes much easier. In this article, we’ll explore how to create a budget for your packaging needs and discuss the key factors that affect packaging costs, from materials to design choices.

1. Understand Your Packaging Requirements

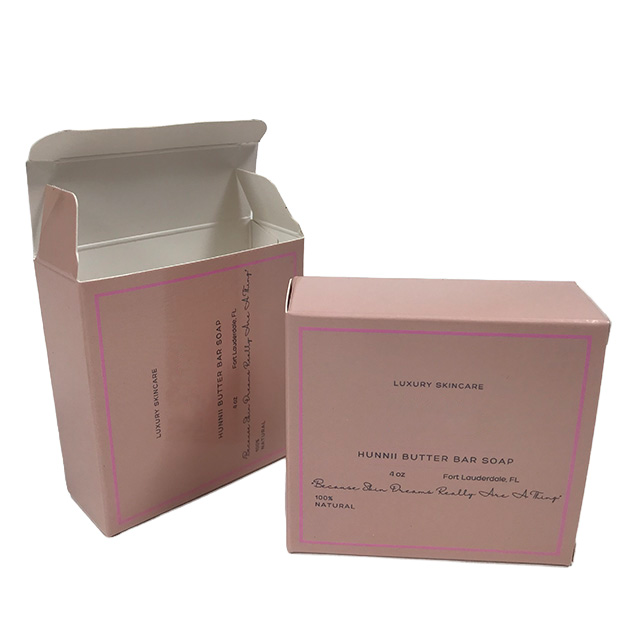

The first step in building your packaging budget is to understand the specific needs of your products. The type of packaging you select will depend largely on the nature of the product itself, as well as your marketing goals and customer preferences. For instance, if you’re selling products like nutrition bars, you may want to opt for display boxes if your items will be sold in retail stores. On the other hand, if you’re selling directly to customers in bulk, folding cartons or mailer boxes may be more appropriate.

Here are a few important questions to ask when assessing your packaging needs:

- Is your product fragile? Fragile products often require extra padding or sturdier materials to ensure they arrive safely.

- Are your products perishable? Perishable goods may require packaging that helps preserve freshness, such as vacuum-sealed bags or insulated boxes.

- Are you packaging multiple products together? Bundles may require larger boxes or custom inserts to keep products securely in place during shipping.

- Are you offering different types of products or bundles? If so, your packaging budget will need to account for different designs and sizes to accommodate various items.

Another important aspect to consider is the type of packing materials you’ll use. From kraft paper to SBS (Solid Bleached Sulfate) paperboard and lamination, the materials you choose will impact both the cost and sustainability of your packaging. Furthermore, your packaging design should align with your sales goals, meaning you’ll need to factor in not only the quantity of packaging required, but also any seasonal variations in demand.

2. What Do Customers Expect from Your Unboxing Experience?

Understanding what your customers expect when they receive your product in the mail can significantly affect your packaging budget. The unboxing experience is one of the first physical interactions customers have with your brand, so it’s important to make it count. Consider the values that your customers hold dear, such as eco-friendliness, customization, or the excitement of receiving a unique product.

Here are a few ways to meet customer expectations while being mindful of your packaging budget:

- Eco-Friendly Packaging: Many customers today prefer eco-conscious packaging, which not only shows your commitment to sustainability but also aligns with their values. Kraft paper and soy-based ink are great options for environmentally friendly packaging.

- Personalization: Customers appreciate a personal touch, such as thank-you notes, discount codes, or free samples. These little details can make a big impact on customer satisfaction and brand loyalty.

- Minimal Waste: Overloading your packaging with excessive materials or waste can frustrate customers. Not only does it add unnecessary costs, but it may also hurt your brand’s reputation. Opt for simple yet effective materials that protect the product without overwhelming the customer with excess packaging.

To save on costs, consider ordering packaging in bulk, which can reduce the unit price of each package. By purchasing larger quantities, you’ll get the best deal and also ensure you have enough packaging to meet demand. Additionally, if your product has any environmental certifications, make sure to display these on your packaging. This helps boost your credibility and gives you an edge over competitors.

3. Prioritize Functionality vs. Aesthetics

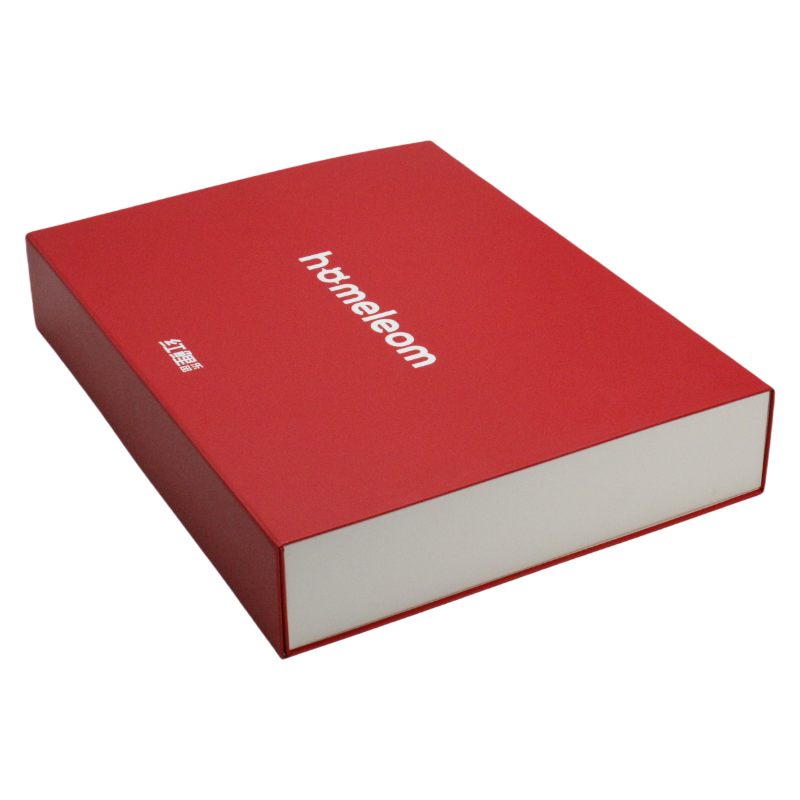

Another key consideration in your custom packaging budget is determining how much emphasis you want to place on functionality versus aesthetics. Both are important, but the amount of money you allocate to each aspect will ultimately depend on your brand identity and customer expectations.

If functionality is your priority, consider opting for materials that are cost-effective yet sturdy, such as kraft boxes. These materials are easy to work with and offer a good balance of protection and sustainability. For less durable materials, like folding cartons, you can include inserts to hold products securely and ensure they are properly protected during shipping.

If your goal is to create an aesthetically pleasing unboxing experience, then you might want to invest more in design elements such as bold colors, special finishes like embossing and debossing, or custom printing. These additional design elements can significantly raise the cost of your packaging, but they may also elevate the customer experience and enhance your brand image.

Additionally, consider the volume of packaging you need. Smaller boxes may be cheaper to produce and ship, but larger boxes, depending on the order size, can also be cost-effective when factoring in minimum order requirements. By assessing the quantity you need, you can determine how to balance cost and design quality effectively.

4. The Importance of Sustainable Materials in Your Budget

In today’s market, sustainability plays a significant role in consumer purchasing decisions. As a result, incorporating eco-friendly materials into your packaging may not only improve your brand’s reputation but also positively influence your budget. Choosing sustainable options, such as biodegradable plastics, recyclable paper, and compostable fillers, can reduce waste and enhance your brand’s commitment to environmental stewardship.

While eco-friendly materials may initially cost more, they can help attract customers who prioritize sustainability, which can lead to greater brand loyalty and increased sales. Additionally, some materials, such as recycled cardboard or plant-based plastics, are both cost-effective and environmentally friendly, making them great options for packaging your products without breaking the bank.

5. Optimizing Shipping and Logistics Costs

Once you’ve accounted for the cost of your custom packaging, it’s time to consider the logistics and shipping expenses. Shipping costs can eat into your overall budget, especially when dealing with bulky or oversized packaging. To optimize your packaging budget, consider how you can streamline the shipping process.

For example, choosing appropriately sized boxes will not only reduce the cost of materials but also minimize the space required for shipping. Avoid using oversized packaging, as this can increase both material costs and shipping fees. By selecting the correct size for each product, you can reduce waste, lower your carbon footprint, and cut costs on shipping.

Another way to reduce shipping costs is to utilize efficient shipping carriers and bulk rates. Many carriers offer discounts for businesses that ship in high volumes, so consider partnering with a logistics provider that offers bulk shipping rates or discounted services based on your shipping needs.

6. Track Your Packaging Expenses for Future Optimization

Building a packaging budget is not a one-time exercise. As your business grows, your packaging needs will evolve, and it’s essential to track your spending over time to identify areas for optimization. By analyzing your packaging expenses regularly, you can identify cost-saving opportunities, whether it’s through purchasing in bulk, reducing excess packaging, or switching to more affordable materials.

Additionally, keep an eye on consumer feedback regarding your packaging. If customers express dissatisfaction with packaging materials or size, you can make adjustments for future orders, improving the customer experience while keeping costs under control. Regularly evaluating your packaging costs and customer feedback will allow you to make informed decisions and keep your packaging budget on track.

Conclusion: Building a Practical Packaging Budget

Setting a packaging budget is an essential step in ensuring that your product reaches your customers in a way that reflects your brand’s values while remaining cost-effective. By considering factors such as product type, customer expectations, sustainability, and the balance between functionality and aesthetics, you can create a packaging strategy that meets your business goals and fits within your financial parameters.

Remember, your packaging is a reflection of your brand. While staying within budget is important, investing in high-quality, sustainable packaging can pay off in the long run by boosting customer satisfaction and brand loyalty. Keep tracking your packaging expenses and optimizing your strategy to create the best possible unboxing experience for your customers.

FAQs About Setting a Packaging Budget

How much should I allocate to my packaging budget?

On average, brands spend around 10% or less of their product budget on packaging. However, this can vary depending on factors like product size, design complexity, and the materials used. It’s important to allocate a portion of your budget based on the specific packaging needs of your products and your brand’s goals.

What are some cost-effective materials for packaging?

Eco-friendly materials such as kraft paper, recycled cardboard, and biodegradable plastics are cost-effective options that align with sustainability trends. They offer a good balance of quality, functionality, and affordability, making them excellent choices for packaging your products.

How can I optimize my shipping costs with packaging?

To optimize your shipping costs, choose appropriately sized boxes for each product, as oversized packaging increases both material and shipping costs. Additionally, using efficient shipping carriers and taking advantage of bulk shipping discounts can help reduce logistics expenses and improve your overall packaging budget.