Sadržaj

Folding cartons have become an essential component of secondary packaging, widely used for a variety of products across industries. These paperboard cartons are lightweight, easy to store, and cost-effective. As the packaging industry continues to evolve, understanding the folding carton manufacturing process is crucial for any business looking to create standout packaging solutions. This comprehensive guide will walk you through the entire journey of how folding cartons are made—from the initial design concept to the final product ready for shipping. Let’s dive in!

1. The Importance of Folding Cartons in Packaging

Folding cartons are a popular choice for packaging due to their flexibility, cost-effectiveness, and ability to protect products during transportation. The unique advantage of folding cartons is their ability to be shipped flat, minimizing shipping costs, and assembled when needed. This space-efficient feature makes them an attractive option for businesses looking to streamline their packaging processes.

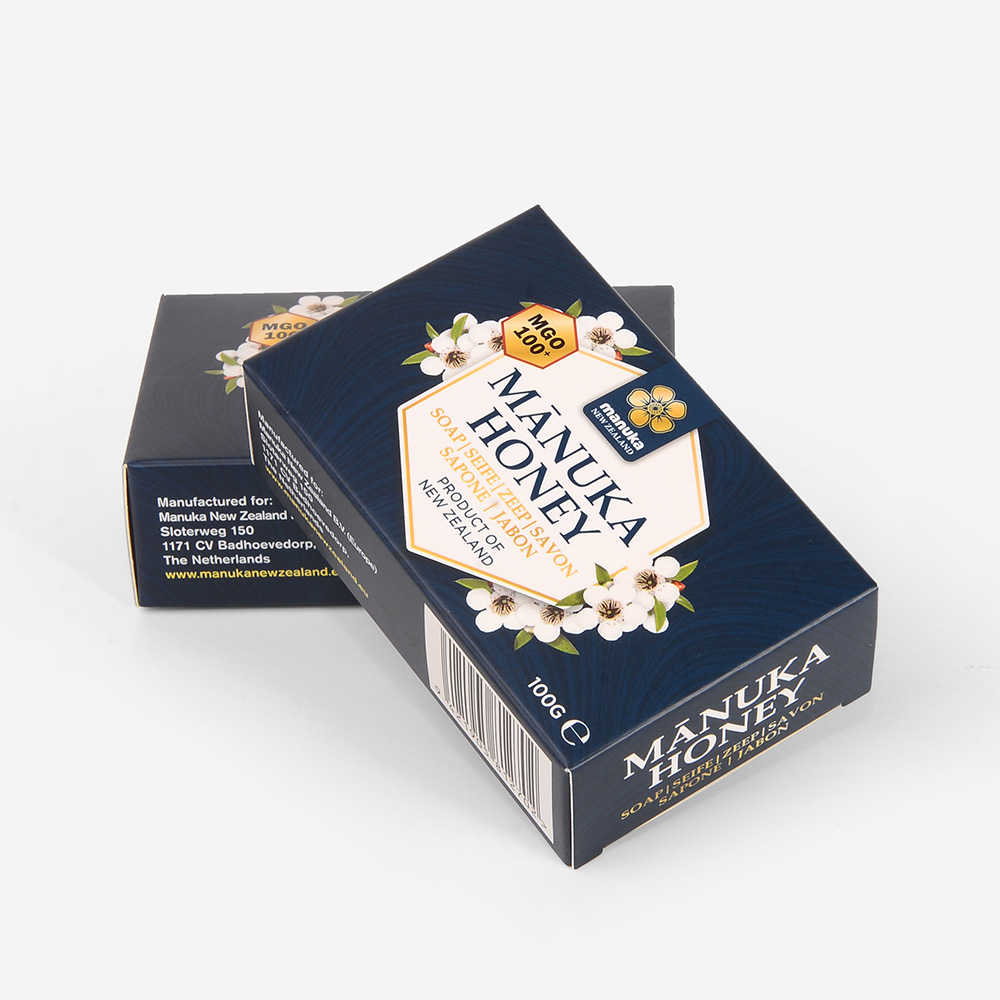

Not only do folding cartons offer practical benefits, but they also provide an opportunity to enhance a brand’s image through creative and customized designs. Custom folding cartons allow businesses to differentiate their products and create a unique unboxing experience for customers.

2. The Folding Carton Manufacturing Process Overview

The process of manufacturing folding cartons involves multiple steps, each requiring precision and attention to detail. After a design is finalized, it is handed off to folding carton manufacturers who use a combination of technology and craftsmanship to bring the concept to life. The process typically follows these stages:

2.1 Step 1: Die-Lines and Sheet Layout

The first step in the folding carton manufacturing process involves the creation of die-lines. Die-lines are the flat, two-dimensional outlines that indicate where the paperboard will be cut, folded, and glued. These lines serve as a guide for both the die-cutting and assembly processes. Additionally, die-lines will show the placement of artwork, allowing designers to visualize where logos, graphics, and product information will be positioned on the final packaging.

In offset sheet-fed production, these die-lines are used by the prepress department to create the ‘sheet layout.’ The layout is optimized to maximize the number of cartons that can be produced from a single sheet, ensuring cost efficiency while minimizing material waste. Once the layout is designed, it is prepared for printing, with the die-lines and artwork ready for the next phase of production.

2.2 Step 2: Sheeting and Printing

Before the paperboard can be printed, it must be sheeted. Paperboard typically arrives from the supplier in large rolls, which are then cut into individual sheets to fit into the printing press. The sheeting process ensures that the paperboard is cut precisely, with the grain running in the correct direction for optimal folding.

Next, the paperboard sheets are fed into the printing press, where high-quality inks are applied using the sheet layout. This is the stage where vibrant colors, intricate graphics, and detailed product information are transferred onto the sheets. Various ink and coating units are used to achieve different visual effects, including matte, glossy, and textured finishes that can enhance the overall appearance of the packaging.

2.3 Step 3: Post-Press Finishes

After the sheets have been printed, additional finishing processes may be applied to enhance the visual appeal and functionality of the packaging. This can include techniques such as hot foil stamping, embossing, and debossing, which add texture and shine to the packaging.

Hot foil stamping uses heat to transfer metallic foil onto the surface of the paperboard, creating eye-catching accents. Embossing and debossing, on the other hand, involve raising or lowering specific areas of the carton to create a tactile effect that adds dimension and sophistication. These finishes help to elevate the perceived value of the product, making it more attractive to consumers.

2.4 Step 4: Die-Cutting

Once the printing and post-press finishes are complete, the next step is die-cutting. The die-cutting process involves using a custom-made die, which works like a cookie cutter to cut the printed sheets into the desired shapes and sizes. The die also includes rounded protrusions that create creases along the folding lines, ensuring that the cartons fold easily and cleanly.

Die-cutting is an essential step in maximizing material efficiency, as the die is designed to minimize waste by cutting multiple cartons from a single sheet of paperboard. After the individual cartons are cut, the remaining paperboard is collected and recycled, contributing to sustainability efforts in the packaging industry.

2.5 Step 5: Folding and Gluing

With the die-cut pieces ready, the next step is folding and gluing. During this stage, the flat pieces of paperboard are folded along the pre-scored creases and glued to create the three-dimensional carton. Some folding cartons may also require transparent windows for product visibility, which are typically added during the folding and gluing process.

The goal of this stage is to create a folded and glued carton that can be easily filled with the product. The folding and gluing machines are optimized to perform these tasks quickly and efficiently, ensuring that the cartons are assembled in as few passes as possible. Once the cartons are fully assembled, they are ready to be shipped to retailers or directly to customers.

3. The Benefits of Custom Folding Carton Manufacturing

Custom folding cartons offer several advantages that make them an ideal choice for businesses looking to elevate their product packaging. Here are some of the key benefits of using custom folding cartons in your packaging strategy:

3.1 Enhanced Brand Recognition

Custom folding cartons provide an opportunity to showcase your brand’s identity through unique designs, logos, and messaging. The ability to tailor your packaging to reflect your brand’s personality helps create a strong, recognizable presence on store shelves and online. By using custom packaging, you can differentiate your products from competitors and ensure that your brand stands out to consumers.

3.2 Sustainability and Cost Efficiency

Folding cartons are lightweight, cost-effective, and environmentally friendly. Many businesses are choosing to use eco-friendly materials, such as recycled paperboard, to reduce their carbon footprint. Custom folding cartons also allow businesses to optimize box sizes, minimizing waste and reducing shipping costs. The space-efficient nature of folding cartons also means they take up less room in storage and during shipping, lowering overall logistics costs.

3.3 Zaštita i trajnost

Folding cartons are not just visually appealing; they also provide protection for your products. The sturdy nature of paperboard helps shield products from damage during shipping, handling, and storage. Custom folding cartons can be designed with features that ensure your products stay safe and secure, including additional protective inserts or cushioning materials that help prevent breakage or contamination.

3.4 Improved Customer Experience

Custom folding cartons can play a key role in creating a positive customer experience. The packaging is often the first physical interaction a customer has with your brand, and custom boxes can leave a lasting impression. The unboxing experience is an important part of the customer journey, and by investing in well-designed packaging, you can create excitement and anticipation. Custom folding cartons make the process of receiving your product more memorable, enhancing overall customer satisfaction.

3.5 Versatility in Design

Custom folding cartons offer unparalleled flexibility in terms of design. Whether you’re packaging skincare products, electronics, or food items, folding cartons can be customized to fit any product. Different shapes, sizes, and finishes can be combined to create packaging that suits your brand’s needs and product specifications. From simple designs to intricate, high-end finishes, the possibilities are endless.

4. Sustainable Packaging Solutions with Folding Cartons

As sustainability becomes an increasing concern for consumers, many businesses are looking for eco-friendly packaging solutions. Folding cartons are an excellent option for businesses that want to reduce their environmental impact while still providing high-quality packaging. Many paperboard manufacturers use recycled materials to create folding cartons, making them a more sustainable choice compared to plastic or other non-biodegradable packaging options.

4.1 Using Recycled Paperboard

Recycled paperboard is a great way to reduce the amount of waste generated by packaging. By using recycled materials, businesses can help reduce their carbon footprint and promote a more sustainable future. Many consumers now prefer brands that prioritize eco-friendly practices, and using recycled paperboard in your custom folding cartons can enhance your brand’s reputation as a responsible business.

4.2 Biodegradable Options

For businesses that want to take their sustainability efforts even further, biodegradable folding cartons are available. These cartons break down naturally over time, minimizing their environmental impact and reducing landfill waste. Biodegradable packaging options are a great way to show your commitment to the environment while still offering high-quality, attractive packaging for your products.

5. FAQs about Folding Carton Manufacturing

5.1 What are the main advantages of using custom folding cartons for packaging?

Custom folding cartons offer several benefits, including enhanced brand recognition, cost efficiency, sustainability, and improved customer experience. They also provide strong protection for products during shipping and handling.

5.2 Can folding cartons be customized to fit any product size?

Yes, folding cartons can be tailored to fit a wide range of product sizes and shapes. Whether you’re packaging small skincare bottles or large electronics, folding cartons can be customized to suit your needs.

5.3 How do custom folding cartons help businesses with branding?

Custom folding cartons allow businesses to showcase their logos, designs, and brand messaging, helping to create a unique and memorable identity. Custom packaging helps your brand stand out from competitors and increases the chances of product recognition and customer loyalty.

6. Conclusion: Why Custom Folding Cartons Are the Future of Packaging

Custom folding cartons are an essential part of modern packaging, offering businesses the opportunity to enhance their brand identity, improve customer satisfaction, and provide durable, cost-effective solutions. Whether you’re looking to increase product protection, improve sustainability, or create a memorable unboxing experience, custom folding cartons can help your business succeed in a competitive market.

By investing in high-quality, customized packaging, you’re not just protecting your products—you’re investing in your brand’s future. The right folding carton packaging can make all the difference, creating a lasting impression with customers and driving long-term success for your business.

.